In a liquid cooling system, cold plates are in charge of transferring heat from high-heat load surfaces to the fluid used. To select the best liquid cooling solution for your application, you must determine the cooling fluid flow rate, fluid inlet temperature, the heat load of the devices attached to the cold plate, and maximum desired cold plate surface temperature Tmax. From these values, you can calculate the cold plate's maximum allowable thermal resistance.

Liquid Cooling Cold Plate Use Cases

- Dense server racks

- Supercomputing server blades

- High-power laser systems

- Military and civilian vehicles

- Fuel cells

- Battery systems

- High thermal performance – Up to 5 [kW] power dissipation per plate

- Low thermal resistance (plate-to-liquid)

- High-pressure burst proof: Tested at 400 [psi]

- Leak proof: Tested at 300 [psi]

- Manufactured using a convectional CNC milling process

- Lightweight

- Low liquid-pressure drop (input-to-output)

- Easy connections to user system

- Standard quick-release couplings

- Blind-mate, no-spill couplings. (Can be modified according to customer requirements)

- Adapters (optional)

- Hard anodized coated (for galvanic corrosion protection)

- Allows secure connection/ disconnection of the coupler/ nipple, without damaging the cold plate

- Adjustable flow orifice – pressure control according to requirements

- Thermal/ flow & structural analyses

- All plates are tested to verify performance (ATP)

- Controlled Design Parameters

- Plate shaping according to heat dissipation map

- Max plate temperature rise

- Flow rate consideration & Pressure drop

- Geometry and weight

Milpower Source designs and manufactures liquid-cooled cold plates for ground, naval, and airborne military applications, such as power supplies, communication products, and more. We offer off-the-shelf solutions, with relatively short lead times. These products can also be modified to meet a customer’s specific requirements, provided the modification can be implemented on an existing design, and fully customized designs, along with thermal/ flow analyses, to deliver an optimized solution according to customer requirements. Configurations created for specific requirements will be assigned a new variant part number.

New, Innovative Products

|

|

|

|

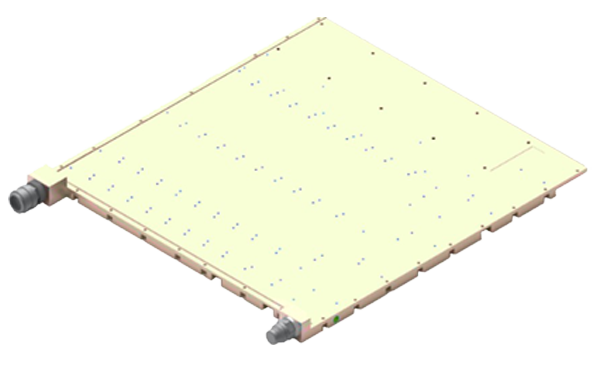

M3001-1 Liquid Cooled Cold Plate |

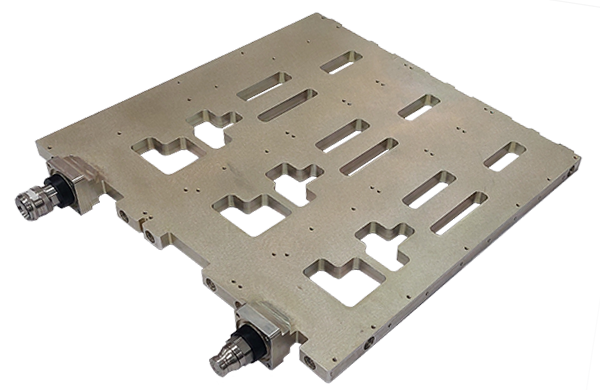

M3002-1 Liquid Cooled Cold Plate |