In today’s electronics landscape, effective thermal management is not just a necessity but a critical factor in ensuring optimal performance and longevity of electronic systems. At Milpower, we specialize in providing advanced thermal management solutions tailored to meet the unique challenges faced by ground, naval, and airborne military applications.

Beyond our renowned expertise in power supplies and communication solutions, Milpower excels in implementing cutting-edge cooling technologies that maximize efficiency and reliability.

Understanding Electronic Cooling Systems

Electronic cooling systems are integral to dissipating the heat generated by components such as processors, power supplies, and amplifiers. Efficient thermal management not only prevents overheating but also enhances overall system performance and extends operational lifespan.

By effectively managing heat, electronic devices can operate reliably under demanding conditions, ensuring mission-critical functionality.

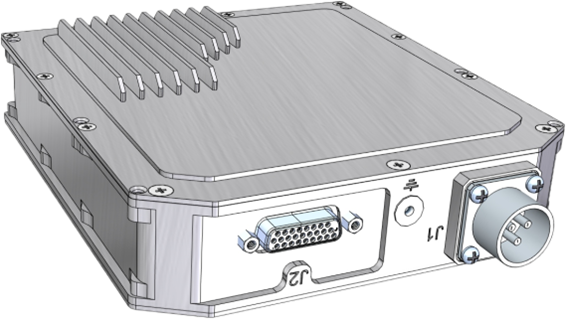

For instance, the Miltech 3433 GDT is engineered for ground operations and features a "pin-fin" heat sink that effectively dissipates heat in multiple airflow directions. It is worth noting that it can be used both for natural and forced convection cooling. Additionally, it includes a custom-designed cover to mitigate the impact of solar radiation on the heat sink. The unit is also painted to enhance its emissivity, thereby improving heat dissipation into the environment by radiation.

Milpower's Comprehensive Thermal Solutions Capabilities

Conduction and PCB Exchange

We offer a wide array of thermal management capabilities designed to address diverse cooling challenges:

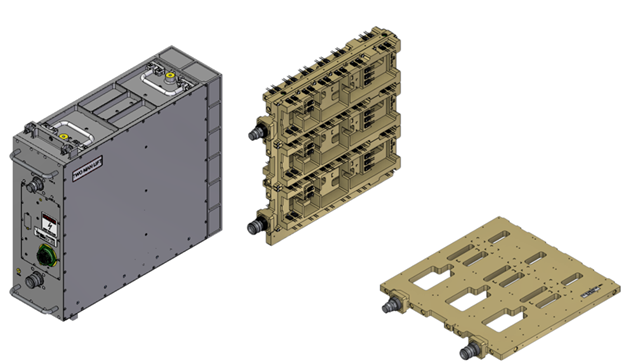

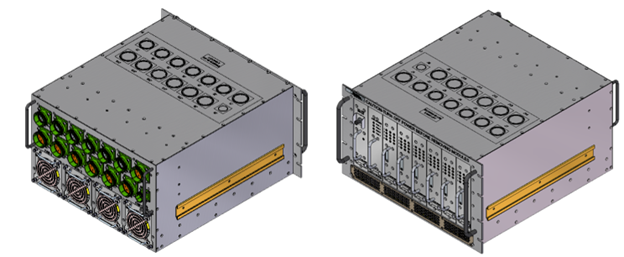

Conduction—Rack Cooling (VITA): At Milpower, our solutions for rack-mounted systems represent the pinnacle of thermal engineering. Utilizing advanced conduction techniques, we excel in efficiently transferring heat away from critical components, ensuring optimal performance even in the most challenging environments characterized by confined spaces and high heat loads.

Our expertise in VITA standards ensures compatibility and reliability across military and aerospace applications, where reliability under extreme conditions is paramount. By leveraging innovative thermal management strategies, including high-efficiency heat spreaders and conductive materials, we maximize heat dissipation while minimizing thermal gradients that could compromise system performance.

The M1660 is a great example of a power supply designed for ground operations, utilizing a liquid-cooled cold plate for heat dissipation. The cold plate features a symmetrical design, with components installed on both sides, enabling a relatively short heat path from the component to the coolant. By using a liquid with high thermal properties, this design effectively dissipates approximately 3 kW from the modules to the cold plate with relatively small temperature gradient.

This approach not only enhances operational reliability but also extends the lifespan of electronic components, reducing maintenance costs and downtime. Whether for ground-based command centers, naval vessels, or airborne platforms, Milpower's rack cooling solutions are engineered to meet stringent performance requirements and operational demands, providing peace of mind in mission-critical scenarios.

For example, the M1233 is an airborne power supply that utilizes Forced Convection for heat dissipation. The primary feature of the heat exchanger is its ability to combine heat dissipation with weight optimization, thereby reducing the power supply's overall weight.

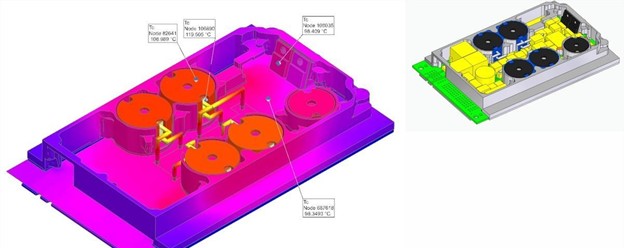

Regarding airborne power supply, the M3624 employs fans for forced convection and heat dissipation. A key feature of its heat exchanger is fan redundancy, which ensures continuous operation even if one of the fans fails.

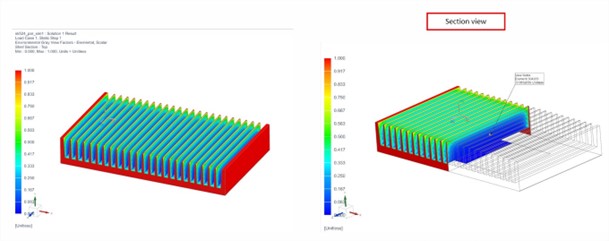

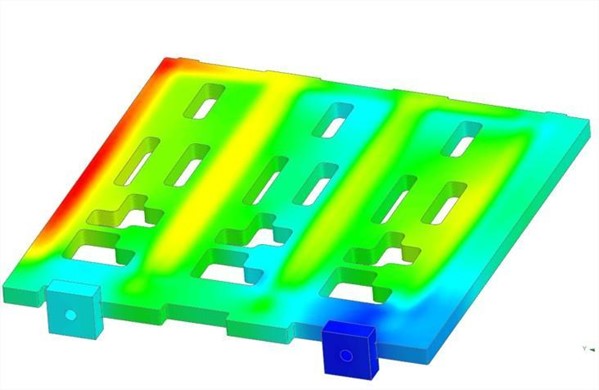

PCB Exchange: A standout capability at Milpower is our sophisticated software-driven approach to thermal management. Prior to product development, our software analyzes logical and physical information to predict temperature increases accurately.

This capability enables us to optimize thermal performance by considering internal traces, vias, and component power dissipation, ensuring precise thermal management from the initial design stages.

Transient Solutions: We specialize in managing transient power conditions, which are critical for handling sudden spikes in power dissipation that can affect electronic system stability and reliability.

Our advanced transient power management techniques are designed to effectively mitigate these challenges and ensure consistent performance under varying load conditions.

By employing sophisticated algorithms and real-time monitoring, we proactively anticipate and respond to transient events, thereby minimizing thermal stress on components and preventing performance degradation. This approach not only enhances system reliability but also extends the operational lifespan of critical electronic equipment.

Whether for military applications where rapid response and resilience are essential, or in industrial settings requiring robust performance under fluctuating operational loads, Milpower's expertise in transient solutions delivers peace of mind and operational efficiency.

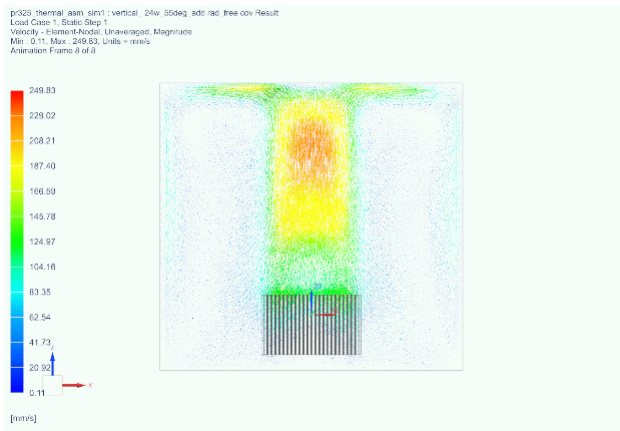

Natural Convection and Combined Air Flow Designs: Our expertise extends to designing highly efficient heat sinks that capitalize on natural convection and integrate seamlessly with advanced PCB exchange technologies.

This integrated approach not only maximizes cooling efficiency but also minimizes energy consumption, making it particularly advantageous for applications that prioritize passive cooling solutions. By strategically incorporating optimized fin geometries and heat dissipation pathways, our designs enhance convective heat transfer while maintaining compact form factors suitable for diverse electronic systems.

This holistic approach ensures that thermal management is both effective and sustainable, supporting long-term reliability and performance stability across a range of operational conditions.

Whether in rugged military environments where silent operation and minimal maintenance are critical, or in industrial settings where energy efficiency is paramount, Milpower's natural convection and combined air flow designs deliver superior cooling solutions tailored to meet the most demanding requirements.

Our approach ensures that cooling solutions are meticulously optimized for exceptional thermal performance and operational efficiency across a diverse range of applications.

By leveraging advanced computational methods and simulation tools, we accurately predict heat dissipation and airflow dynamics, allowing us to tailor solutions that meet stringent performance requirements.

Our designs maximize heat transfer rates through efficient convection mechanisms, ensuring robust thermal management in environments where effective heat dissipation is critical.

Whether enhancing cooling efficiency in high-power electronic components or optimizing thermal resilience in aerospace and defense applications, Milpower's radiation and forced convection solutions deliver reliability and performance excellence, setting a benchmark in thermal management innovation.

Liquid Cooling Systems

Milpower offers robust liquid cooling solutions designed to meet stringent performance requirements:

Liquid Cooled – Cold Plate: Our cold plates are engineered for high thermal performance, capable of dissipating up to 5 kW of power with minimal thermal resistance and high-pressure tolerance. They undergo rigorous testing to ensure reliability under extreme conditions, making them ideal for applications in power supplies, amplifiers, and server rooms.

Advantages of Milpower's Approach

Milpower sets itself apart in the thermal management industry through its comprehensive and integrated approach to cooling solutions. Unlike many competitors, we possess a unique capability to conduct thorough and detailed analyses that encompass all critical physical factors affecting thermal performance.

Our expertise extends beyond mere component-level cooling; we delve deep into the intricate dynamics of thermal conductivity, heat dissipation mechanisms, and airflow dynamics.

With advanced computational modeling, simulation tools, and decades of engineering experience, we ensure that every aspect of our cooling solutions is meticulously optimized.

This rigorous approach enables us to predict and mitigate potential thermal challenges well before they arise, ensuring that our solutions not only meet but often exceed customer expectations for reliability and performance.

Whether designing for ground, naval, or airborne applications, we tailor our solutions to withstand extreme environmental conditions while maintaining peak operational efficiency.

Our commitment to innovation and reliability drives us to continually push the boundaries of thermal management, delivering solutions that are robust, efficient, and engineered to perform under the most demanding circumstances.

Conclusion

In conclusion, effective thermal management is fundamental to optimizing the performance and longevity of electronic systems. Milpower's commitment to innovation and reliability is evident in our diverse range of thermal solutions, from advanced PCB exchange technologies to high-performance liquid cooling systems. Whether you require standard off-the-shelf solutions or customized designs tailored to specific requirements, Milpower stands ready to meet your thermal management needs with precision and efficiency.

For more information on our thermal management solutions, including our comprehensive range of products and customization options, please contact us today.